Calaca Works

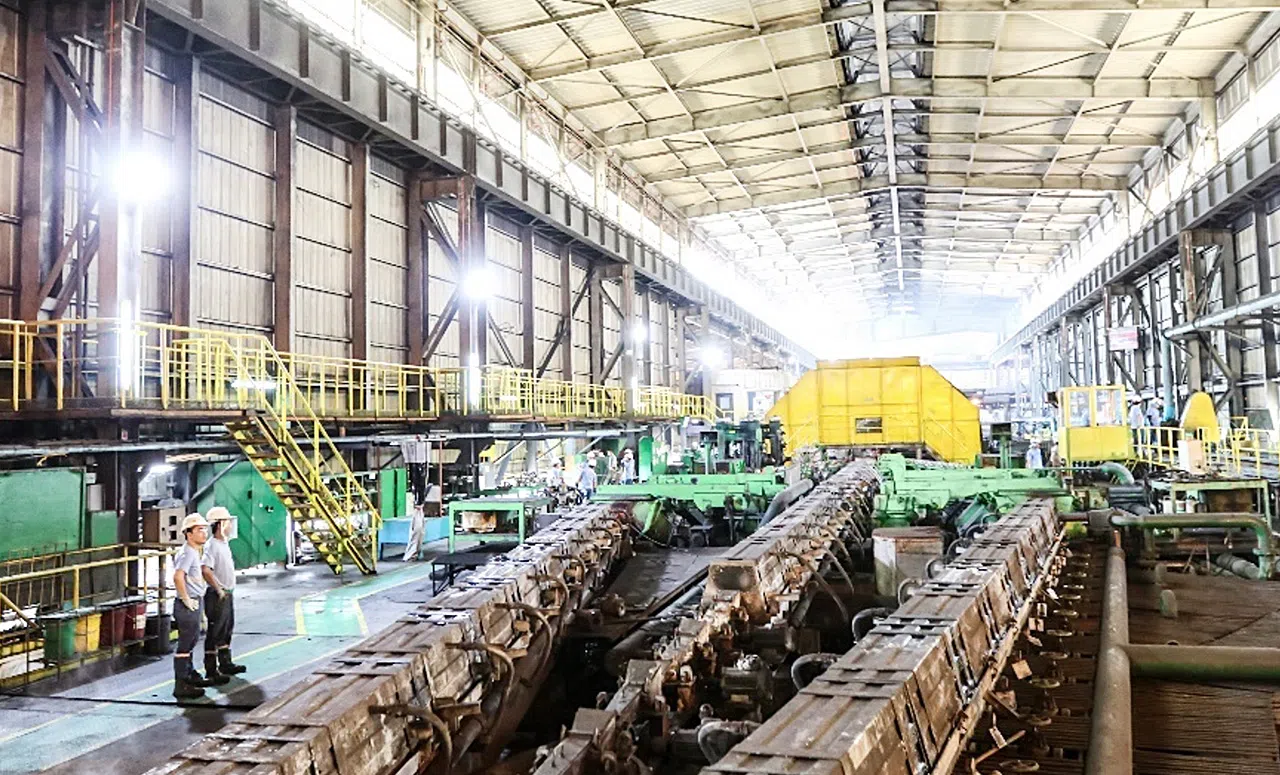

Calaca Works of SteelAsia houses a mini-mill or an integrated rebar line. The rebar line is directly integrated with its scrap-based billet production.

SteelAsia Calaca Works is unique because it is the only integrated steel works facility in the Philippines. It sits on a 17-hectare lot inside the Calaca Industrial Seaport (formerly Phoenix Petro terminal and Industrial Park) in Batangas.

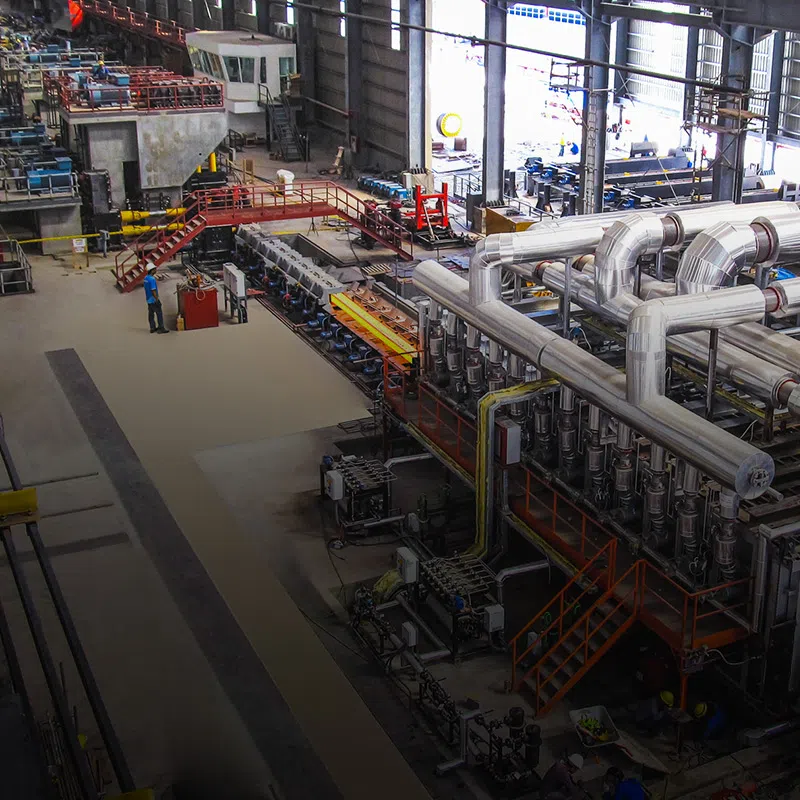

The process is unique as steelmaking is linked to rolling. It recycles domestically purchased scrap steel that is melted and cast into semi-finished steel called billets. The newly cast red-hot billets are then charged into the rolling mill facility. This is called direct hot charging. It saves up to 40% on fuel consumption, compared to simply buying and feeding cold billets into the rebar line. This manufacturing line is called M3.

The original 300,000 tons per year (tpy) mill was established in 1999 by Bacnotan Steel Industries, a venture among the Phinma Group, Kawasaki, Mitsui, and local banks. However, it was mothballed a year into operation under the weight of the Asian financial crisis.

SteelAsia acquired the facility from its consortium of creditors in 2007. After rehabilitating and upgrading the facility, it was re-commissioned in 2008 with an increased capacity of 500,000 tpy.

Mostly using Japanese technology and equipment, the mill has a twin high-speed tungsten carbide monoblock. M3 was the first mill to use this technology, which made it possible to produce small rebar sizes with high precision while maintaining speed and productivity.

The use of modern technologies — such as quick size change, in-line rolling train configuration, independent drives, and Level-2 automation — also brought the mill to world standards of productivity, conservation, and operational health and safety.

Calaca Works Offers:

PNS49 Rebar (sizes 10mm to 50mm, lengths 6M to 15M) Grade 550 (ASTM Grade 80) regular and weldable Grade 520 (ASTM Grade 75) regular Grade 420 (ASTM Grade 60) regular and weldable Grade 280 (ASTM Grade 40) regular and weldable Grade 230 (ASTM Grade 33) regular

PNS 211 rebar (8mm)

Technical Description

| Mill Type | Steelmaking and Rebar Rolling Mill |

| Electric Arc Furnace |

Nikko (Japan) 70 tph |

| Ladle Furnance | Baosteel Engineering (China) |

| Continuous Casting Machine | Mitsubishi Heavy Industries (Japan) |

| Reheating Furnance |

Sanken Sangyo Co., Ltd. (Japan) 70 tph |

| Rolling Mill |

Kawatetsu (Japan) 500,000 tpy Continuous, Straight Line Rolling Mill 14 Horizontal - Vertical Rolling Stands |

| High Speed Block Mill |

Sumitomo Morgan (Japan) Twin 4-stand |

| Automation | Level 2 |

| Re-Commissioned | 2008 |