Davao Works

Also known as M5, Davao Works is home to the Philippines' largest and most modern steel mill. It was commissioned in 2014 as one of two mills in the Mindanao region.

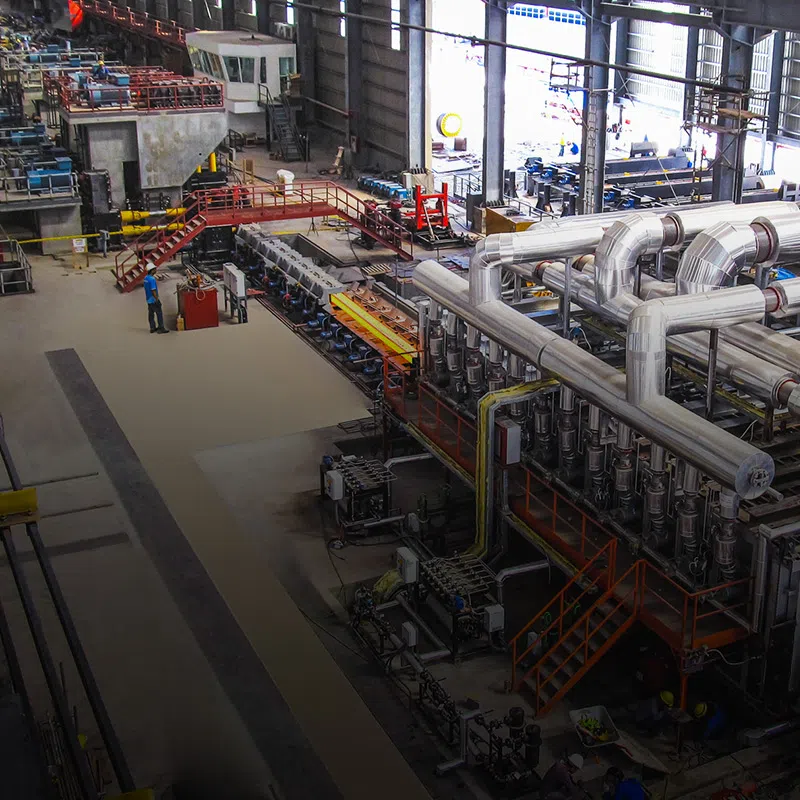

Located at Bunawan District in Davao City, Davao Works is the Philippines’ largest and most modern steel mill with 600,000 tons per year capacity.

The rolling mill is state-of-the-art and among the most modern in the world. It features the latest technologies for productivity, energy conservation, environmental impacts and operational health, and safety.

It is an Italian-designed and supplied mill. M5 is the first Philippine steel mill with the capacity to process 150mm x 150mm billets, a more economical specification and a world standard today. M5 is also the first Philippine mill to use AC motors, which are power-efficient, low-noise, and low-maintenance equipment. The mill also features a twin tungsten carbide monoblock that can produce PNS 211 7mm and 8mm bars. M5 is also the first Philippine mill equipped with rotating drum technology.

The environmental features of M5 stand out: utilizes 150,000 cu.m. of water and sources the vast quantity exclusively from rainwater collected from the Work’s roofing and road system and stored in a reservoir. There is zero effluent draining into the environment, as 100% of wastewater is recycled and treated, then re-used in operations. There is zero seepage of oil into the ground. The machinery is lubricated via a closed system that combines air and oil, and the lubricant is distributed through hydraulics.

Like SteelAsia’s other mills, the automation and other technologies in its design also ensure energy conservation and the lowest possible particulate emission.

Davao Works Offers:

PNS49 Rebar (sizes 10mm to 50mm, lengths 6M to 15M) Grade 550 (ASTM Grade 80) regular and weldable Grade 520 (ASTM Grade 75) regular Grade 420 (ASTM Grade 60) regular and weldable Grade 280 (ASTM Grade 40) regular and weldable Grade 230 (ASTM Grade 33) regular

PNS 211 rebar (sizes 7mm and 8mm)

Cut and Bend Services

Technical Description

| Mill Type | Rebar Rolling Mill |

| Reheating Furnance |

Formi Industriali Bendotti (Italy) 80 tph |

| Rolling Mill |

Revas/Studio Crespi (Italy) 500,000 tpy Continuous, Straight Line Rolling Mill 14 Horizontal-Vertical, Rolling Stands Housingless, Cartridge-Type-Rolling Stands |

| High Speed Block Mill |

Revas/Studio Crespi (Italy) Twin 6-Stand |

| Automation | Level 2 |

| Commissioned | 2014 |