Raising the bar:

Reliability.

Management. Technology.

Reliable Service

When SteelAsia expanded and modernized, Philippine developers and builders began to enjoy, for the first time, better and more reliable service. Reliability is being there at the right time and place. Imagine trucks of wet concrete ready to be poured and having to wait for the steel rebar, which may or may not arrive. Customers would certainly prefer to sleep easy the night before knowing with certainty that SteelAsia’s rebar will be where it is supposed to be, at the time when it is supposed to arrive.

SteelAsia’s reliability is part technology, part capacity, and part workforce.

Customer coordination and support

Behind the technology and heavy machinery is an expert and experienced team of customer care specialists. They make sure that they know exactly what you need and more. They find out all conditions of your delivery site, load limitations, truck limitations, time constraints among others. They work with this information coordinating and adjusting plant production schedules, plant logistics and third party trucking ensuring stock is ready and delivered just-in-time. They also prepare all the sampling, commercial and technical documentation that customers need.

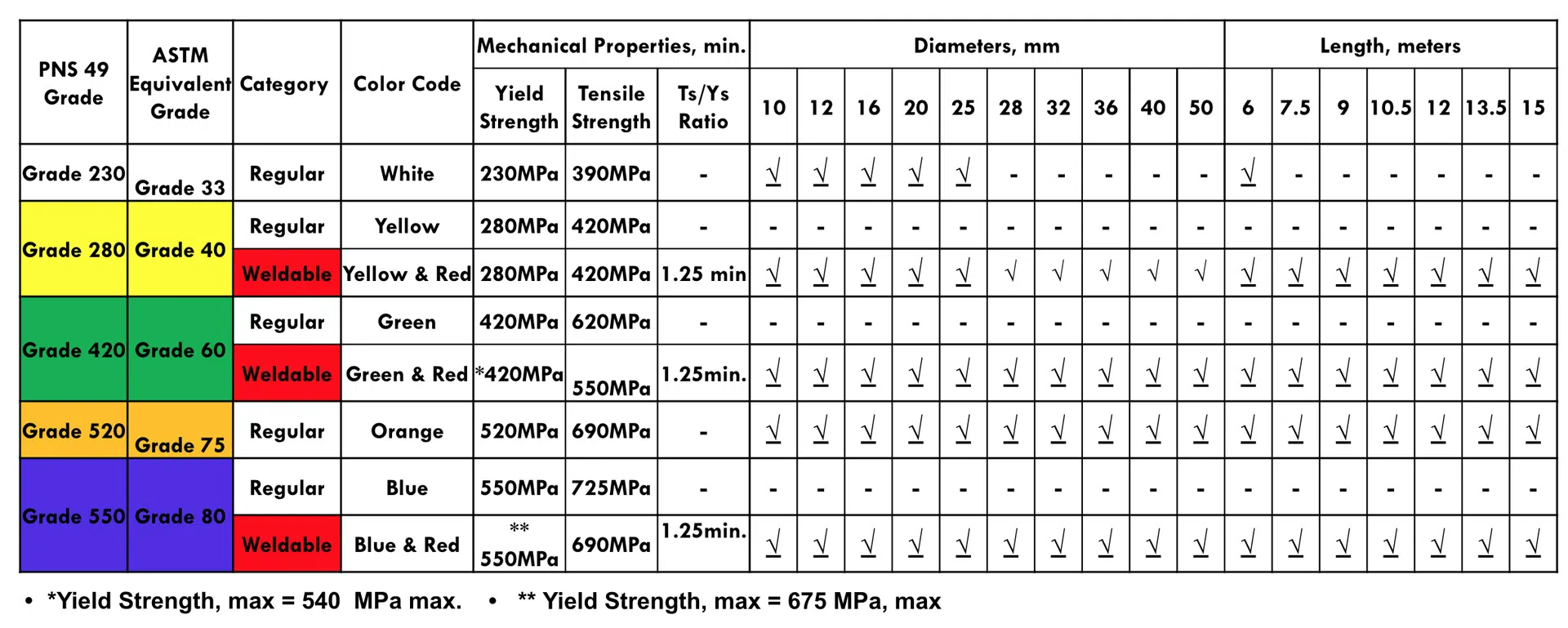

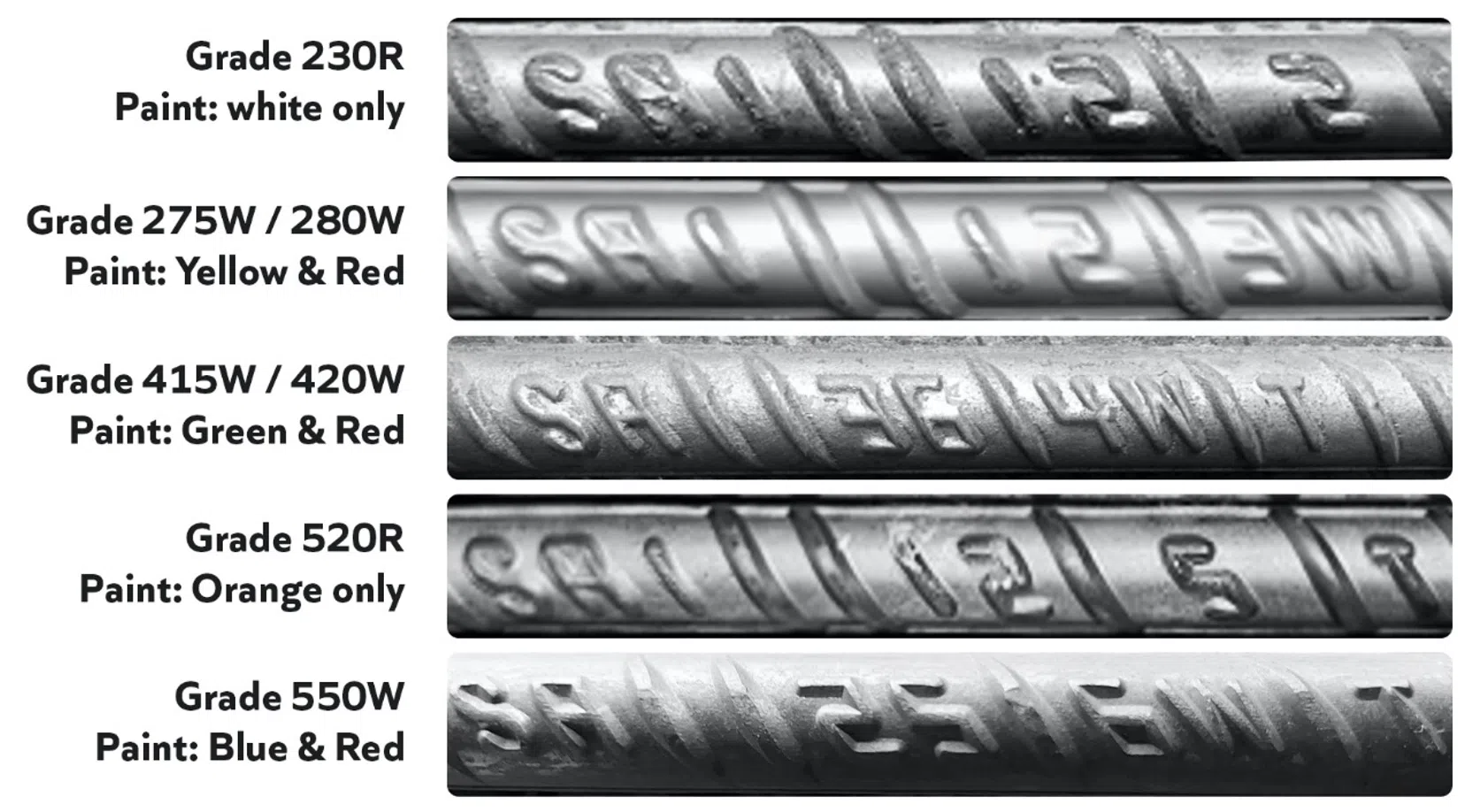

Full range of rebar product capability

Only SteelAsia does it all. The Philippine National Standard for rebar (PNS49) lists all the specifications. Unique to SteelAsia is its one-stop-shop capability for rebar. No need to go mill shopping to complete the grocery list of rebar items. All strength grades, all sizes, and all lengths are manufactured by SteelAsia.

Rebar Management Solutions

Our customers create value by building better structures, not by managing rebar logistics. SteelAsia’s rebar management solutions shift rebar management from customers to us - the rebar company, leaving our customers to focus on their real business.

One-stop-shop

SteelAsia is the only rebar company that manufactures ALL the different specifications in the Philippine Standard for rebar.

Technical and customer support

Whether you are a homeowner, civil work contractor, property developer, or any other rebar buyer, SteelAsia provides buying and technical assistance including advice on standards, bending, testing, and all other matters of technical nature.

JIT (Just-In-Time)

Customers need not deal with long lead times nor do they need to buy in bulk and store rebar for long periods. SteelAsia provides ANY quantity large or small, will store them for as long as needed- for free, and have them available when needed.

One price policy

SteelAsia now has plants in Luzon Visayas and Mindanao. No matter which plant a customer buys rebar from, it will cost the same. Visayas and Mindanao customers no longer need to ship rebar from Luzon. In the past, Cebu customers paid shipping costs equivalent to shipping from Russia to the Philippines! Davao customers paid more! But today, the price of rebar in Cebu and Davao is the same as in Metro Manila.

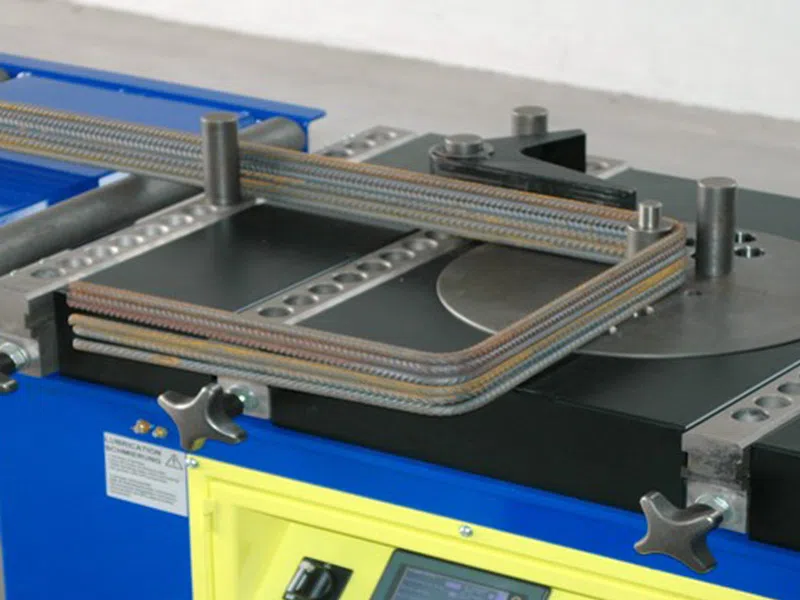

Cut and bend

Cut and Bend is the system of cutting and bending to install-ready specification within a factory setting. It is a widely-used system in developed countries. The cut-and-bend system benefits rebar buyers by reducing the management time and resources needed for rebar works. It also significantly reduces costs by eliminating cutting and error wastage, double-handling, storage, and other site expenses. It involves cutting and bending into shapes of exact specification, in a consistently accurate manner using shear lines and power bending machines, as opposed to manual operation.

Technology

Public safety is SteelAsia’s first priority. To be able to consistently produce to this stringent standard, SteelAsia installs the most modern and technologically advanced equipment into its manufacturing lines. Precision automation and equipment ensure that SteelAsia has the capability to produce to standard at all times.

High quality in an earthquake and typhoon area

The safety of Filipino lives is paramount

The Philippines is in the world’s busiest typhoon belt, and it is also in the Pacific Ring of Fire. In 1991 the Philippine Bureau of Product Standards imposed a mandatory standard on rebar so that as a building material, it would have the necessary strength and other physical characteristics needed for structural integrity to withstand the unusual stresses of natural phenomena. The standard is called the PNS49 (Philippine National Standard), and all companies and individuals that manufacture, import, sell, distribute and use rebar must adhere to its conventions. The standard itself follows ISO 9001 and it includes the special characteristics of rebar which are more commonly known as seismic rebar or earthquake-proof rebar.

Public safety is SteelAsia’s first priority. To consistently produce up to this stringent standard, SteelAsia invests in the most modern equipment in its manufacturing lines. Precision automation and equipment ensure that SteelAsia has the capability to produce to standard at all times. These technologies along with its quality processes that are conscientiously adhered to by SteelAsia employees have earned the company certifications such as ISO 9001 (Quality Management) and ISO 17025 (Quality Testing Laboratory), and UK Cares (British Standard Conformity).

Lowest cost rebar

SteelAsia aims to be part of the solution.

From the broader concept of country development to the case of the humble worker building a lifetime house that will be passed down to the next generations, the cost of construction is often a prohibitive factor. Rebar is one of the highest-cost components of civil works, and the cost of making rebar is largely about technology.

A developing country such as the Philippines needs the support of a resilient domestic steel industry and one that can support construction with the lowest costs. Modern rebar manufacturing technology is naturally more expensive but a necessity to be able to achieve the lowest costs in the long term.

Lowering manufacturing costs requires world-class efficiencies that are the focus of innovative steel manufacturing technologies. Furnace design, rolling train design, motors, and automation are key to:

- Minimizing waste-product (increasing yield)

- Minimizing downtime (increasing productive hours)

- Maximizing speed (decreasing cycle time)

- Minimizing energy use (decreasing power and fuel consumption)

- Minimizing parts consumption (increasing usable life of equipment parts)

- Economies of scale (increasing manufacturing output to cover overhead cost)

Environmental, health and safety management

The first company in the Philippine steel industry to be certified ISO 14001 Environmental Management Systems and ISO 45001 Occupational Health and Safety Management Systems

Embedded into every steel bar that SteelAsia delivers are the technological investments that reduce the environmental impacts, and protect the health and safety of the public and employees of SteelAsia.

- SteelAsia mills have zero wastewater. 100% of the water exiting the operations line are not drained as effluent but rather channeled into a dedicated waste-water treatment facility on the premises, and cycled back into operations.

- SteelAsia has been on the cutting edge of resource-usage minimization. It has implemented rainwater collection, from the roofs of its buildings and roads at its plant site. Rainwater is increasingly the main source of water for SteelAsia, as in its Davao plant operations which operates while recycling 80 cu. meters of rainwater every hour.

- Air-oil lubrication is a new technology that SteelAsia has implemented. Lubrication is in a closed system, rather than an external application of lubrication the latter of which may result in ground contamination from used oil.

- SteelAsia uses automated furnaces. Through sensors and automation, the optimum fuel-air mix is achieved, minimizing particulate emissions. This also ensures optimum burning saving fuel by up to 30% compared to zero-automated furnaces.

- Hot-charging technology reduces fuel consumption further by another 35% in SteelAsia’s mini-mill.

- Furnace stacks are up to 50 meters high ensuring that with air dispersion, emissions stay well below the allowable limits at ground level.

- The pioneering use of AC motors driven by individual Process Logic Controls saves on power consumption by more than 25% and significantly reduces noise levels.

- In-line rolling stands increase the safety of the mill compared to accident-prone cross-country configurations.

- SteelAsia uses heat recuperators to recycle energy and save on fuel.